🔧 Mastering Design for Manufacturing (DFM) in PCB Creation: A Must-Have Skillset for Engineers 🔧

- May 1, 2024

- 2 min read

📚 What's one DFM insight you've recently applied or learned? Share your stories and let's learn together!

In the world of electronics, the beauty of a PCB lies not only in its functionality but also in its manufacturability.

As engineers, it's crucial we continuously refine our Design for Manufacturing (DFM) knowledge to ensure our PCB designs are not just brilliant, but also brilliantly manufacturable.

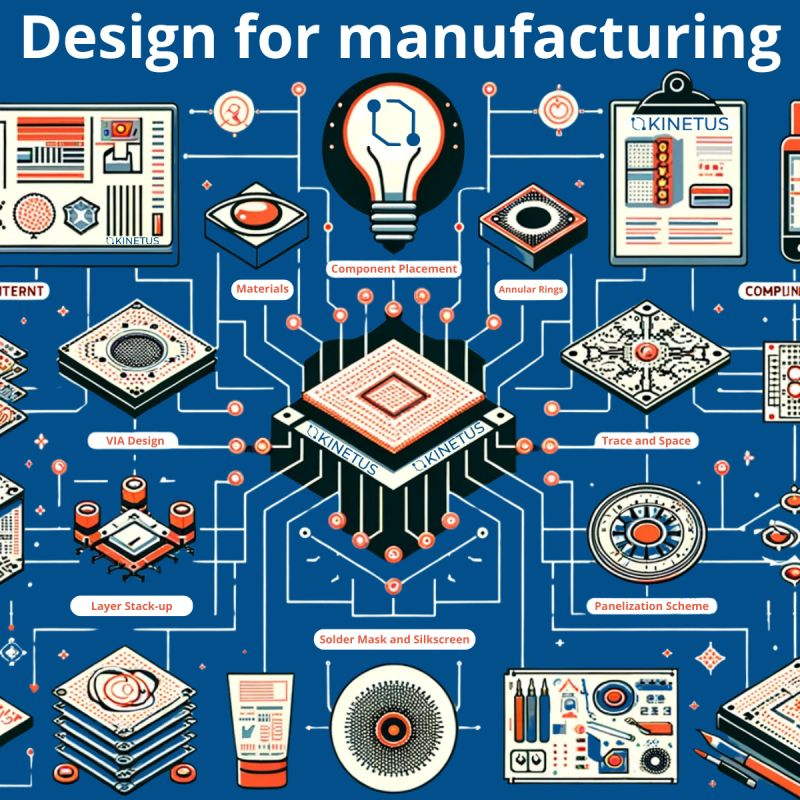

🔧 Mastering Design for Manufacturing (DFM) in PCB Creation: A Must-Have Skillset for Engineers 🔧

1. Component Placement 📍:

Aim for layouts that minimize solder bridging risks and facilitate smooth solder flow. Remember, avoiding densely packed areas eases both soldering and inspection.

2. Trace and Space 🛸:

Work within the manufacturing capabilities for trace width and spacing. This foresight prevents etching issues and unintended shorts, a fundamental yet critical aspect of DFM.

3. Via Design ✍:

Vias need to be sized with the manufacturing process in mind, respecting aspect ratio limits. Tenting vias can be a strategic choice to avoid solder loss, especially during wave soldering.

4. Annular Rings 💍:

Correct sizing of pads and annular rings is non-negotiable for preventing drilling issues. It's a delicate balance that underscores precision in design.

5. Layer Stack-up 🥪:

The layer stack-up should be optimized considering manufacturability, a process that harmonizes cost-effectiveness with performance needs.

6. Materials 🪨:

Selecting the right materials is foundational, taking into account their compatibility with the manufacturing process and the final product’s requirements.

7. Panelization Scheme 🎛️:

Thoughtful design of PCB panels to accommodate depanelization methods protects PCB integrity post-separation.

8. Solder Mask and Silkscreen 🎭:

A well-applied solder mask and clear silkscreen detailing part numbers and orientations significantly enhance assembly accuracy.

As the industry evolves, so do the standards and technologies underlying these DFM principles. Continuous learning and adaptation are our best tools as engineers to ensure our designs not only meet but exceed manufacturing excellence standards.

LinkedIn post:

Comments